Customizable ERP’s Impact on Manufacturing Businesses

Customizable ERP’s Impact on Manufacturing Businesses

Introduction

Business leaders encounter a number of difficulties in today’s fiercely competitive manufacturing environment. Nevertheless, once these challenges are recognized, what makes a good company great is how swiftly it moves to find the best answers and how it stays one step ahead of its rivals. To stay competitive, businesses must first streamline their processes and adjust to changing consumer demands.

The implementation of an Enterprise Resource Planning (ERP) system is one such strategy that helps businesses stay ahead of the curve. Businesses now have access to a wide variety of tools for managing and integrating a variety of areas of their operations thanks in large part to ERPs. Even while conventional ERP systems could have been effective, the advent of customised ERP solutions has totally changed the industrial sector. This blog highlights how customized ERP systems have a significant impact on manufacturing organizations by streamlining operations, increasing productivity, and fostering long-term growth.

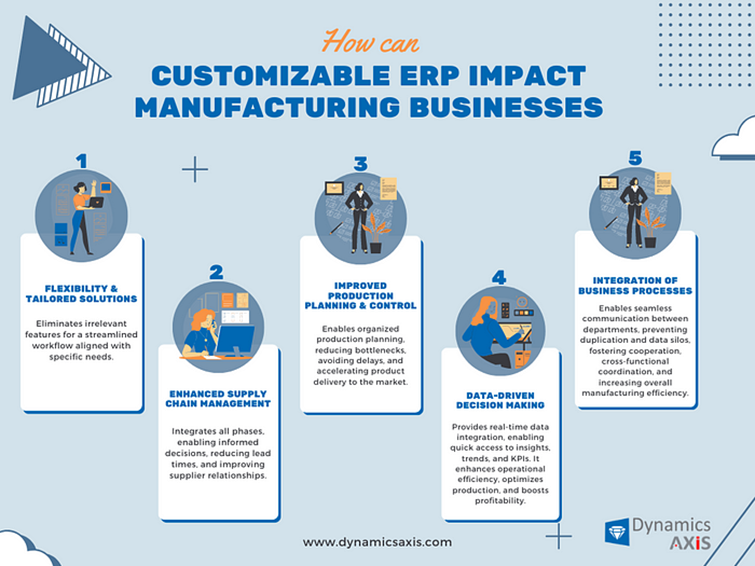

1. Flexibility and Tailored Solutions

For manufacturing companies, the flexibility that customized ERP systems offer is one of their main advantages. Traditional ERP systems usually come with a set of preset features that could not entirely match a company’s particular processes and needs. Contrarily, adaptable ERP solutions give businesses the freedom to pick and change the modules that are most pertinent to their business processes, thereby removing superfluous features and reducing clutter. With this customized approach, businesses can be sure that their ERP systems are configured to meet their unique requirements, resulting in a smooth and efficient workflow.

2. Enhanced Supply Chain Management

The flexibility that customized ERP systems for manufacturing companies offer is one of their main advantages. It’s common for traditional ERP systems to include a set of fixed features that don’t always match a company’s particular processes and needs. Contrarily, modifying modules that are pertinent to an organization’s operations is possible with customizable ERP solutions, which successfully removes unused functionality and reduces clutter. This specialized approach ensures that businesses’ ERP systems are in line with their particular requirements, producing a seamless and efficient workflow.

3. Improved Production Planning and Control

The heart of any manufacturing organization is the planning and management of production. Implementing a personalized ERP system makes it simple to optimize manufacturing operations. Manufacturers may decrease production bottlenecks, eliminate expensive delays, and expedite product delivery by being able to plan and manage production in a more systematic and effective way.

4. Data-Driven Decision Making

By centralizing and integrating many elements of the manufacturing process, these ERP solutions gather vast volumes of real-time data from various departments, including inventory, production, sales, and finance. Useful insights and KPIs are easily accessible to analysts through the use of straightforward analytics and reporting tools. Thanks to this data-driven approach, manufacturing organizations can more quickly identify patterns, identify inefficiencies, and anticipate market demands. By using accurate and current information to make informed decisions about resource allocation, production planning, and supply chain management, manufacturers may improve operational efficiency, optimize production processes, and ultimately increase profitability.

5. Integration of Business Processes

Departments will be able to communicate and exchange data without hindrance thanks to this integration, reducing duplication and data silos. Manufacturing businesses may connect their purchasing, accounting, production, sales, and other vital processes, providing them with real-time operational intelligence. The availability of comprehensive and accurate data for the whole manufacturing lifecycle, from the procurement of raw materials through the delivery of the finished product, is now available to decision-makers. The entire operational strategy promotes collaboration, makes cross-functional coordination easier, and increases overall effectiveness.

6. Compliance & Quality Control

Modules created especially for these ERP solutions‘ industry rules and quality standards are included. By integrating these modules, manufacturers can streamline compliance processes and guarantee adherence to norms and regulations. Additionally, ERP systems facilitate remedial actions by recording and monitoring production processes, finding flaws, and enabling strict quality control procedures. Decision-makers who use customizable ERP systems have immediate access to quality measurements, allowing them to identify issues early and take data-driven steps to raise product quality and operational efficiency as a whole. With better compliance and quality control procedures, businesses may increase customer trust, enhance the reputation of their brand, and succeed over time in a cutthroat sector by utilizing customizable ERP software solutions.

Conclusion

These ERP systems enable manufacturers to streamline their operations, enhance the management of their supply chains, and boost overall operational efficiency by offering personalized solutions that are in line with the business’ operational demands. The ability to integrate several departments and data into a centralized platform enables real-time insights, data-driven decision-making, and cross-functional collaboration. With fewer production barriers, less holdups, and speedier product delivery to market, manufacturing organizations can maintain their competitiveness, adapt to altering market demands, and finally boost profitability. Due to their ability to help businesses remain adaptable and responsive in a global market that is always evolving, customizable ERP solutions have played a significant role in the modernization of the manufacturing sector.