ERP vs. Traditional Logistics Systems: Why ERP Reigns Supreme

ERP vs. Traditional Logistics Systems: Why ERP Reigns Supreme

Providing seamless service and product flows requires a logistical approach in today’s fast-paced and interconnected world. The importance of selecting the ideal logistics management system increases as businesses work to maintain their competitiveness and satisfy client demands. Traditionally, businesses relied on manual processes and disparate systems to handle their logistics operations. However, they are now facing increasing challenges in meeting the demands of modern supply chains. Top ERP systems in Dubai have revolutionized the way logistics is managed. In this blog, we will explore the key reasons why ERP reigns supreme over traditional logistics systems.

What Exactly is Logistics Systems?

Before we find the differences between the ERP and traditional logistics system, we have to get an idea about what a logistics system is.

A logistics system refers to an extensive network of linked procedures, tools, and activities for the control and transportation of products, data, and services from their site of origin to their point of consumption. It includes shipping, warehousing, inventory control, packaging, order fulfillment, and supply chain management. An ERP for logistics management system strives to minimize costs while ensuring an effective and timely flow of goods, optimizing resource use, and satisfying consumer demands. Organizations including suppliers, manufacturers, distributors, retailers, and logistics service providers, must work together. An ERP for logistics system enables businesses to achieve operational excellence, improve customer service, and acquire a competitive edge in the market. This is done by integrating and synchronizing these components. Planning, technological integration, and ongoing monitoring are all necessary for an effective logistics system that adapts to changing market dynamics and consumer expectations.

Traditional Logistics System

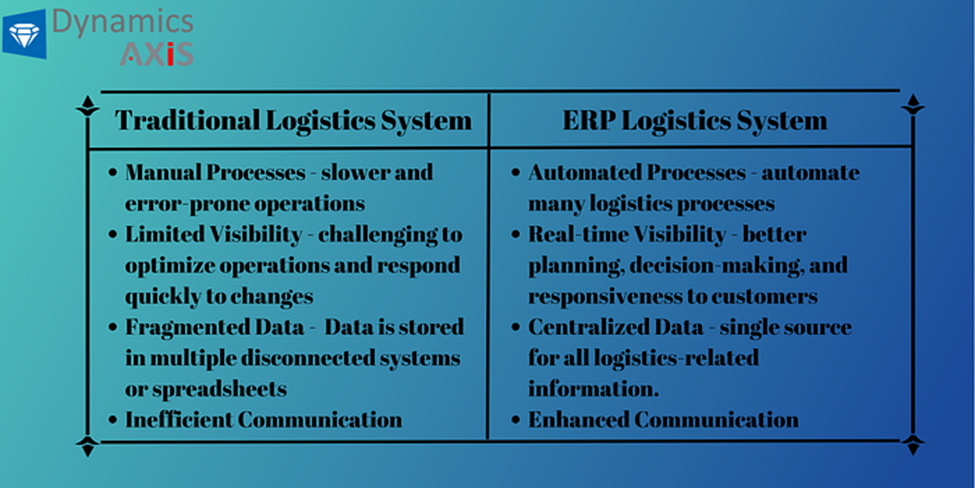

Traditional logistics systems heavily rely on manual processes, including paper-based documentation, manual data entry, and spreadsheet-based tracking. These manual tasks are time-consuming, error-prone, and lack the efficiency needed to keep pace with the speed of today’s supply chains. Moreover, traditional systems often create data silos, making it difficult to access and share critical information across departments or with external stakeholders. This lack of centralized and real-time data management hinders effective decision-making and can lead to operational inefficiencies.

ERP Logistics System Software

ERP systems for managing logistics, from placing orders to delivering goods to customers’ doors, are software solutions that maximize every action. When a user placed an order until it is delivered, businesses use these systems to manage and automate processes in a digital world.

Advantages of ERP Logistics Systems

1. Centralized Data Management

Spreadsheets and other disconnected systems are frequently used in traditional systems, which results in disparities in information and redundancies. ERP unifies all crucial logistical processes, including order processing, transportation, inventory management, and warehouse management. Businesses may obtain accurate data in real-time and with more operational efficiency thanks to this consolidated approach.

2. Enhanced Visibility & Tracking

Traditional logistics systems find it difficult to match the extensive visibility and tracking capabilities offered by ERP systems. Businesses may track shipments, keep an eye on inventory levels, and get real-time updates on the state of their logistics operations with the help of ERP. This thorough visibility guarantees improved supply chain management, enables proactive problem-solving, reduces disruptions, and raises customer satisfaction.

3. Process Automation and Efficiency

ERP is excellent at automating tedious processes, which is essential in logistics operations. Manual data entry, paperwork, and tracking processes are prone to mistakes, holdups, and inefficiencies when using traditional methods. These procedures are automated by ERP, which also reduces paperwork, gets rid of manual errors, and boosts productivity. Logistics experts can concentrate on more value-added activities like strategic planning, customer support, and exception handling by automating typical processes.

4. Communication and Collaboration

It can be challenging for traditional logistics systems to collaborate and communicate between several stakeholders, including suppliers, carriers, and customers. All stakeholders can exchange information and work together efficiently with logistics ERP systems. Through ERP, errors, delays, and miscommunications are reduced, resulting in a more successful and efficient logistics ecosystem.

5. Scalability and Adaptability

Logistics operations are dynamic, and businesses need systems that can scale and adapt to changing requirements. Traditional logistics systems often lack the flexibility and scalability necessary to accommodate growth and changing business needs. ERP systems, on the other hand, are designed to be scalable and adaptable, allowing businesses to easily add new functionalities, integrate with other systems, and handle increased transaction volumes. This scalability ensures that businesses can keep up with evolving logistics demands and remain agile in a competitive market.

Conclusion

As businesses aim to optimize their logistics operations, ERP systems have emerged as the superior choice over traditional logistics systems. With centralized data management, enhanced visibility, streamlined communication, process automation, and scalability, ERP revolutionizes the way logistics is managed. By implementing an ERP system specifically tailored for logistics, businesses can gain a competitive edge, achieve operational excellence, and deliver superior customer experiences. Embracing ERP is not just a technological upgrade; it is a strategic decision that empowers businesses to reign supreme in the logistics landscape.